If a rubber farm was optimized to improve the latex production and increase the income of its farmers and tappers using an “improved” technology, what would it looks like?

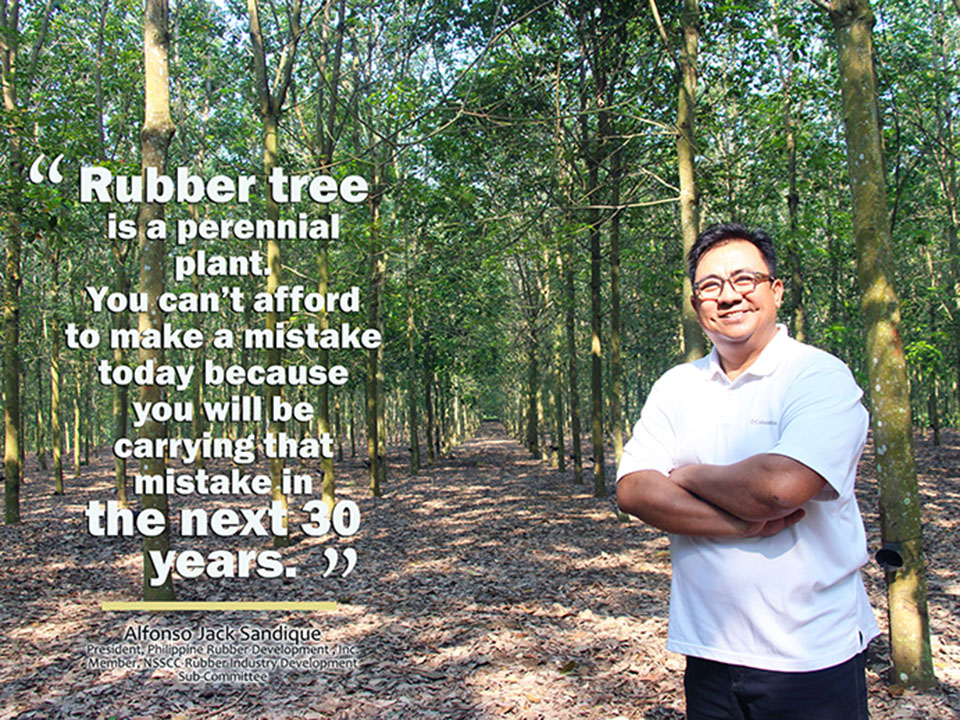

This is what Alfonso Jack Sandique showed to the Philippine Council for Agriculture and Fisheries (PCAF)- Knowledge Management Team during an interview right in the middle of their rubber farm in Makilala, North Cotabato in September.

The Platinum Rubber Development Incorporated (PRDI) is one of the biggest rubber farms in North Cotabato, which is owned and managed by the Sandique family.

At an early age, Sandique showed interest to farming because of the influence of his father, who was an agriculturist from Pangasinan, and his three uncles from his mother’s side.

“This is a family business and since the day I was born, we already have rubber trees. Aside from this, my late father was also involved in rice production. It was also my uncles who trained me because we have farm orchards that has mangosteen, rambutan and others,” Sandique narrated.

Despite the number of agricultural products that his family manages, he opted to focus on the rubber industry, noting that rubber is the main crop of PRDI.

Discovering the improved technology

In 2001, Sandique met his mentor, the late Guillermo “Gil” Igot who agreed to share all his knowledge about rubber farming in one condition: to share it to the small stakeholders.

From that day, he carried the expertise Gil Igot shared with him, did further research on how to transfer the technology, and started an advocacy that would ensure farmers higher latex production and yield.

This “improved” technology cuts across from the selection of seedlings in the nursery, selection of bud woods, land preparation, production of quality planting materials, shifting to “big planting bags” from “small bags”, performing maintenance activities, and even in tapping and collection of latex or cup lumps and scraps.

Sandique started to introduce the technology by doing lectures to various groups of rubber farmers in 2007, however, he suddenly stopped in 2014.

“I haven’t done any lecture since 2014. I was trying to teach everybody what to do and nobody would listen because they would say that this technology is only possible in big rubber farms or corporations, but I can assure you, this is possible for small farms. It can be done,” he shared.

Sandique also mentioned that he has not seen the government launch a true program for the rubber farmers. With the creation of the Philippine Rubber Industry Roadmap 2017-2022 and with the new Agriculture Secretary, he is looking forward for a shift in the industry and its stakeholders.

“Rubber tree is a perennial plant. You can’t afford to make a mistake today because you will be carrying that mistake in the next 30 years,” he said.

The rise of the sunset industry

“If you would ask me ‘What is the situation of the rubber industry in the Philippines?’, I would say it is a sunset industry. Planting rubber will only promote poverty in farmers’ lives,” Sandique revealed.

“For example, if a farmer has one hectare of rubber trees, then they are having a harvest of 20 kilos a day and the harvest is every three days. For a month, they can only harvest for 10 days, that would make 200 kilos a month.

Then they could sell it for PhP20 per kilo, they can earn a total of PhP4,000. Unfortunately, they need to split it 50-50. Fifty percent for the tapper and 50% for the owner. They both have PhP2,000 each for a month or less than PhP100 a day. Do you think that is below poverty line?” Sandique explained.

In the adoption of the “improved” technology, he can guarantee an earning of at least three times higher than the latter computation, which uses the traditional farming system.

“We could control the production, but we can never have a hand on the prices. Our advocacy to adopt the improved technology is not magic, however, it is very hard to explain because one should see how it is done,” he added.

He is also glad that the Technical Education and Skills Development Authority (TESDA) National Certificate II has already revalidated its protocol for the rubber production. According to him, TESDA was able to capture the framework of PRDI’s “improved” technology.

“I am very optimistic that the small holders, who has been using the traditional farming technique, once they see it and fully understand it, they will somehow ask the government to assist them and have a farm that will be similar to this,” pointing to the rubber trees, straightly planted, keeping a parallel distance.

Sandique said that with PCAF’s National Rubber Stakeholders’ Summit, many rubber farmers and stakeholders witnessed how the technology is done through the field visit.

“When I met Sec. Dar, he told me that there are things that need to be done. As private sector stakeholders and industry leaders, our assignment is to identify these things. He also guarantees that we have his support to achieve these things, as long as we will meet the ‘ani’ and ‘kita’, which our technology offers,” he said.

With the assured support from Agriculture Sec. Dar and the policy recommendations of the rubber stakeholders from the Summit, he is certain that he will finally see sunrise to a setting industry.

The “improved” technology: From soil prep to tapping

Seed preparation/ selection

Nursery

Budding

Planting

Tapping

Pest and disease management

Sharing of Knowledge

###

| JC